Large Scale GTL Operations

Problem

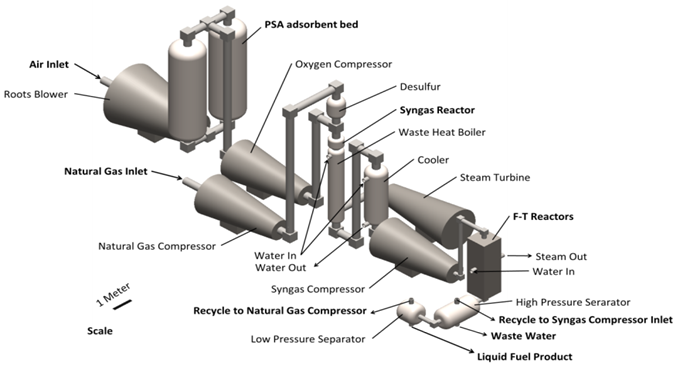

Existing large scale GTL plants are extremely capital intensive and process on the order of 100,000 bbl/day of GTL product, funded by major integrated oil companies. Furthermore these companies have plans to expand capacity and build similar new projects. However, these projects largely rely on less efficient technology such as steam methane reforming or autothermal reforming.

Dason's Proposed Solution

Major integrated oil companies have invested heavily in research on Partial Oxidation but thus far have been unsuccessful in commercializing the process. Dason's revolutionary improvement on catalyst and reactor design is commercially viable from both an economic and operational perspective, and could vastly improve the operating efficiency of large scale plants. Dason's technology is ideal for upgrading current large scale plants because of its:

- Ability to scale up without losing efficiency

- otential for parallel construction which reduces shut down time

Given the scale of these plants, incremental increases in efficiency from using the Dason process have immense impact on the overall product yield. Dason Technology can be used to replace the syngas phase of the reaction and make use of the existing plant equipment for the Fischer-Tropsch phase of the reaction.

Design/Engineering Services

Technology

Design/Engineering Services

Technology